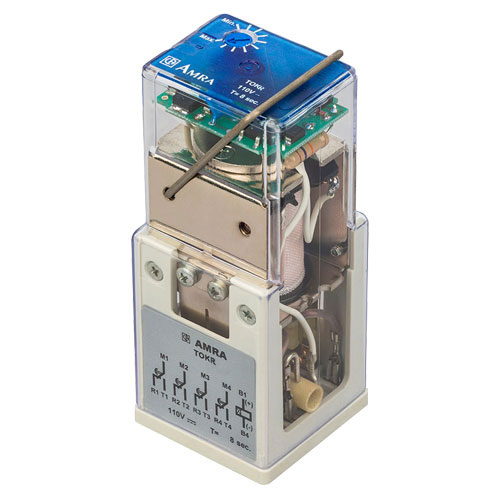

TOKR

- Plug-in relays with time delay on drop-out and magnetic arc blow-out

- 4 timer contacts, 10 A

- Time setting from 0.1s to more than 1 hour by means of potentiometer

- Solid and rugged construction for intensive duty

- Excellent shock and vibration resistance

- Ample clearance between open contact elements, 5 kV insulation

- Mechanical life expectancy of 100,000,000 operations

- Wide variety of configurations and customizations

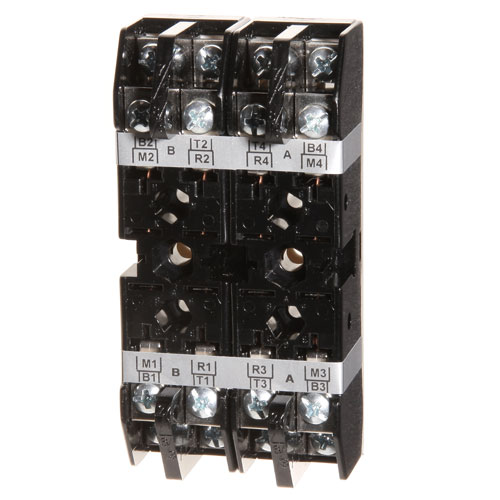

- Wide range of sockets

- Transparent cover, pull-out handle

- Retaining clip for secure locking of relay on socket

- Positive mechanical keying for relay and socket

TOK series plug-in relays, created on the OK platform, designed and built with materials and solutions that impart excellent characteristics of endurance and ruggedness; suitable for use in harsh operating environments and when subject to strong thermal shocks. Above all, these relays can be used in seismic environments thanks to their excellent resistance to shock and vibration.

Time delay on drop-out, switching time selectable from 0.1s to more than 1 hour. Switching time selector comprising 1 turn potentiometer. Switching time setting from 10 to 100% of full scale.

The excellent electrical and mechanical performance of these relays allows them to be used in the most demanding sectors, such as control and signalling functions in electricity generating stations, electrical transformer stations, rail transport, or in industries with continuous production processes.

Magnetic arc blow-out, ample contact clearance, exceptional efficiency in breaking DC loads and pulsed 5 kV insulation between open contacts.

Patented operating mechanism: mechanical life expectancy > 100,000,000 operations.

The contacts are mounted on individual and independent blades, deigned to assure unparalleled pressure values on the make and break contacts, in the region of 0.8…1N. Sliding and self-cleaning contact.

- EN 61810-1, EN 61810-2, EN 61810-7 Electromechanical elementary relays

- EN 61812-1 Time relays

- EN 61812-1 Time relays

- EN 60695-2-10 Fire hazard testing

- EN 50082-2, EN 61000-4 Electromagnetic compatibility

- EN 60529 Degrees of protection provided by enclosures

- EN 60077 Electric equipment for rolling stock - General service conditions and general rules

- EN 50155 Electronic equipment used on rolling stock

- EN 61373 Shock and vibration tests, Category 1, Class B

- EN 45545-2 Requirements for fire behaviour of materials and components – Product No. EL10 – Requirement R26, V0

- ASTM E162, E662 Standard Test Method for Surface Flammability of Materials, Standard Test Method for Specific Optical Density of Smoke

Download technical drawings 2D/3D

LOGIN / REGISTRATION- Connection: Front

- Terminal type: Spring clamp

- Mounting: Panel /DIN Rail

- Wire max (mm2): 2 x 2.5

- Operating temperature: -50…+70°C

Details

- Connection: Front

- Terminal type: Screw

- Mounting: Panel /DIN Rail

- Wire max (mm2): 2 x 2.5

- Operating temperature: -25…+70°C

Details

- Connection: Front

- Terminal type: Screw

- Mounting: Panel

- Wire max (mm2): 2 x 2.5

- Operating temperature: -25…+70°C

Details

- Connection: Rear

- Terminal type: Spring clamp

- Mounting: Panel

- Wire max (mm2): 2 x 2.5

- Operating temperature: -50…+70°C

Details

- Connection: Rear

- Terminal type: Screw

- Mounting: Panel

- Wire max (mm2): 2 x 2.5

- Operating temperature: -25…+70°C

OBSOLET PRODUCT

Details

- Connection: Rear

- Terminal type: Double faston

- Mounting: Panel

- Wire max (mm2): 2 x 2.5

- Operating temperature: -25…+70°C

Details

- Connection: Rear

- Terminal type: PCB pins

- Mounting: PCB

- Wire max (mm2): -

- Operating temperature: -25…+70°C

Details